COLLIER LOGGING MUSEUM, OREGON; BIG WHEEL LOGGING CART/WAGON

Nestled in the forests of Eastern Oregon is one of those rare gems of an outdoor museum, dedicated to the preservation and presentation of logging history. The State of Oregon oversees the museum and surrounding trails and campgrounds. Over the years, I have visited this facility, and watched it develop from a storage place for relics of logging artifacts, to a carefully designed presentation of the equipment once used to harvest timber. The artifacts on display include logging carts and wagons, mill machinery, cabins, railroad cars, and all the accoutrements that made logging possible.

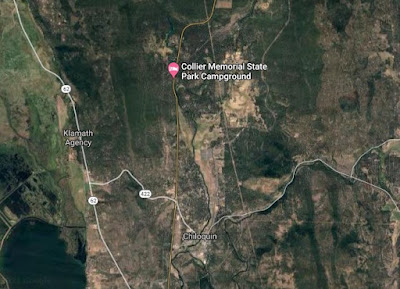

Collier Memorial State Park (located North of Klamath Falls.) You can Web search for additional information. As of May 2021, camping area and trails were closed to repair forest fire damage. The museum is open; however, check the website for hours of operation.

The museum displays may have changed since my last visit (2019?.) The theme remains the same- an outdoor museum displaying the history of logging equipment from the Pacific Northwest.

The museum and camp grounds are situated in park-like setting. Sadly, as of 2021 it has been reported that large areas of forest were burned in this area, including a number of homes. The museum appears to have been saved.

********

Our main focus at the moment are the Big Wheel logging wagons or carts. Additional information about the museum will follow this section.

The museum contains one of the largest collections of Big Wheels, with several designs being represented.

Another view of a big wheel cart. You can see the lever is in the raised position; tongue is pulled forward.

The Michigan big wheels were invented by Silas C. Overpack in 1875. He was a wheel right in Manistee, Michigan, who by observing the actions of a local farmer, and the application of American ingenuity, designed the now famous big wheel logging wagon (technically a cart, since it is based on one axle with two wheels.) Considering that the Saginaw and the Manistee operations and Mr. Overpack were once "neighbors" in the great state of Michigan, it is no wonder that the technology was used in Arizona. His design -easily recognized by the red paint and highlighted by metal parts painted in black- were used extensively by the logging industry until the 1920s. Equally adaptable to rough terrain or the snow and ice of winter, they could be seen working in the forests from Maine to California, and from Arizona to the Pacific Northwest. There were other companies that designed and built similar wagons, as can be seen in the museum's collection.

( Stein, Pat; Cultural Resources Management; Logging Railroads of the Coconino and Kaibab National Forests; Report Number 19, page 130; United States Department of Agriculture, Forest Service. July 2006 :

Mendocino Coast Model Railroad and Historical Society website: mendorailhistory.org.: Project.geo.msu.edu/geogmich/big_wheels.html.)

This is a slide tongue wagon, as opposed to a fixed tongue. A slide tongue allowed the horse team to pull the tongue forward, thus raising the log and reducing friction. If they they needed to stop or slow down, the team simply stopped. A lever system and sprockets controlled the log chain, which was placed around the log. It would take a power point presentation to explain it better; best visit the museum and see it for yourself.

The tongue and mechanism is in the lowered position

A close up view of the mechanism. As the wagons aged and the blacksmiths were kept busy with other chores, often the mechanism was done away with, and the chain was wrapped anyway possible to keep the logs secured. After all, if you're payed by the logs moved to the landing, you find a way to get it done.

A restored Big Wheel at the front gate. The center disk in each wheel helped reduce the chance of a stray branch or obstruction from damaging the wheels. An early form of a deflector screen; and you thought Star Trek was all science fiction.....

An example of the evolution of the Big Wheel to the arch type log carrier. This design incorporated changes, including the use of steel in construction. The Tongue has been changed to allow clearance for the logs, while being pulled by a tractor.

bull dozers, which are caterpillar type tractors ( I say this because a number of manufacturers made these tracked denizens of the forest, not just the Caterpillar Company.), replaced the horse drawn wagons. A number of variations are on display

An example of the logging arch and a caterpillar type tractor. The log would have been suspended under the arch. Machines tend not to be too concerned with small or large rocks or uneven terrain, wherein a horse could be pulled-up lame by such conditions. As seen in the prior picture, bulldozer blades on the tractors helped to clear larger obstacles. As the Forest Service matured, new guidelines were introduced that restricted the use of mechanized logging, thus reducing the long term damage to the forest.

View of an earlier, simplified arch.

****************

The main visitors center, in the form of a logging structure commonly found in the woods. The best place to begin your visit is at the center, where you can pick up a guide to the outdoor exhibits.

Inside the center a variety of displays, such as the daily diet of a logger. Food was one of the more enjoyable aspects of logging. A Loggers life was otherwise wake at an early hour, followed by demanding physical labor. Loggers that endured these conditions were often a proud bunch, tough, hardened and took their work seriously. The introduction of mechanized logging techniques helped to increase production, but also introduced new hazards for the logger. New machines usually meant less demand for manpower, however specialized skills required to operate the steel beasts meant higher wages. Cross cut saws and axes were replaced by chain saws, much to the relief of the loggers. However, chainsaws also required constant attention to avoid injury. A logger took special pride in falling a tree exactly where he wanted it. The logging industry is still rated as one of the higher risk occupations for personal injuries.

throughout the grounds are information signs, giving insight as to the living conditions in the logging camps.

A very informative timeline as to the evolving changes in logging technology

The museum includes displays representing early living conditions,

including cabins and small stores.

A single spool, steam powered donkey engine. Donkey engines were used extensively in the Pacific Northwest and California. They also employed several techniques to drag and load the timber that were seldom seen in the South West, such as "highline" yarding. The use of Donkey engines is a bit of a question mark for the Saginaw and Manistee, and requires more research.

Steam powered mill machinery, common to the larger mills. A boiler house would provide the steam to power the engines.

A Mc Giffert stiff boom loader. This allowed the empty log cars to pass under the main assembly. As the cars were loaded, they were pulled forward, then the process was repeated. Loading could speed up resulting in greater efficiency. However, this was not the case for all of the logging operations. The Saginaw and Manistee purchased a used loader from a Flagstaff company, similar to this one, only it was larger and more complicated. The end result was the machine was sidelined. Sometimes the old, tried and true technology works better for your logging outfit.

The museum has numerous other artifacts and displays. It is a pleasant and informative stop along the highway, and well worth the visit. I hope you enjoyed this brief detour from the Saginaw and Manistee Lumber Company.

No comments:

Post a Comment